This test is to be used annually to test fire apparatus that has a fire pump with 250 gpm or larger capacity or if the pump and or engine on the apparatus have been repaired or modified.

Fire pump testing flow chart.

Flows are in u s.

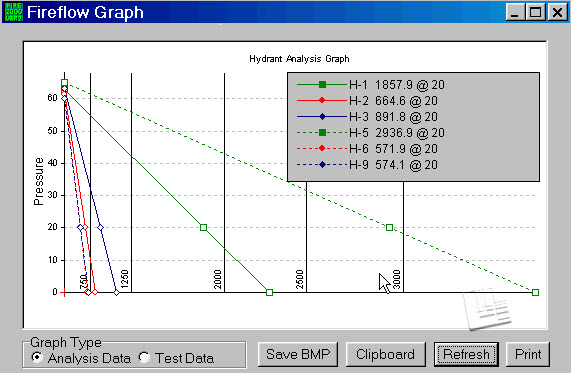

This application has auto adjusting axis divisions and automatically calculates avaliable flow or pressure at a single point.

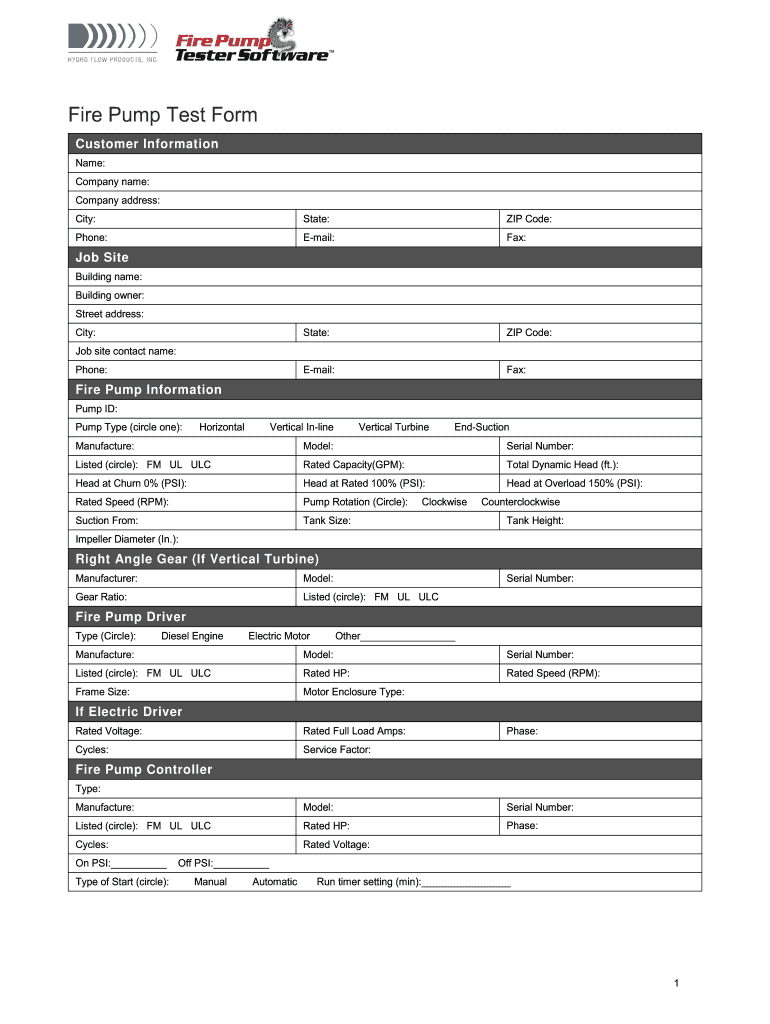

Fpt stores all of your fire pump information calculates flow rates and graphs pump test curves.

Use fire pump tester software to collect fire pump test results professionally comprehensively and easily.

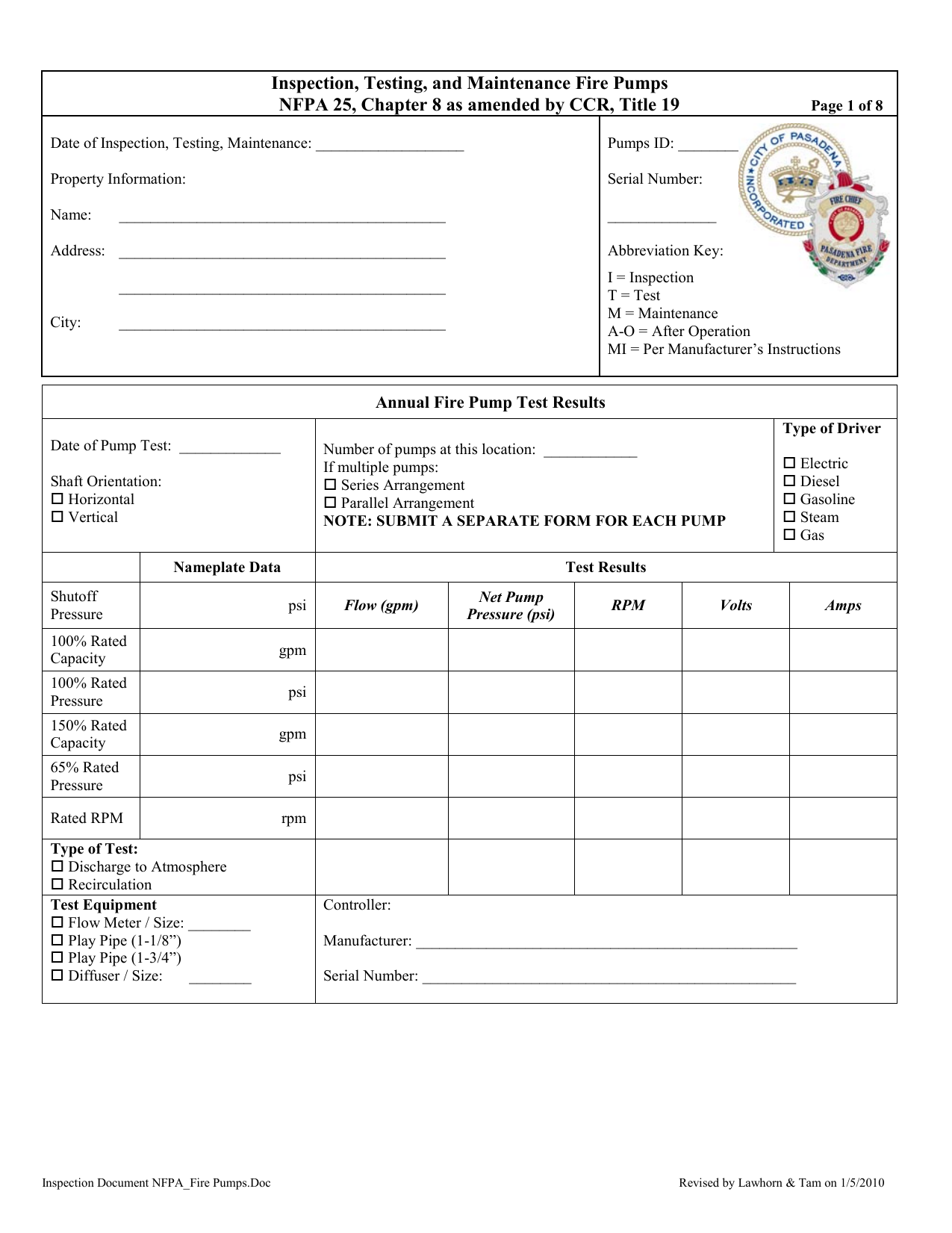

The following information provides an overview of the requirements.

The test should be performed by attaching hoses to the discharge test header.

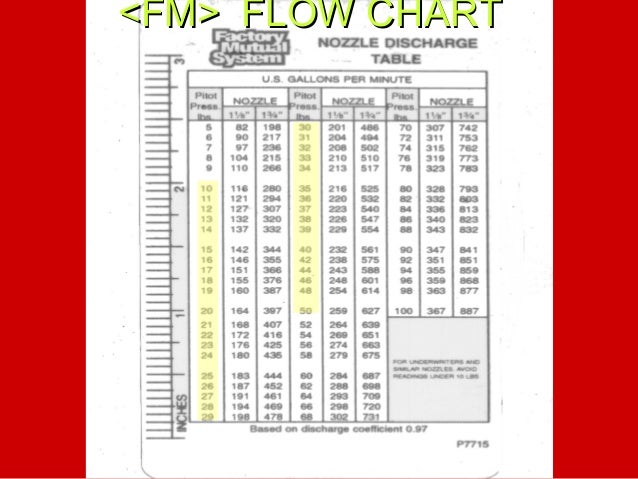

The chart below lists the common solid bore nozzles used in testing fire pumps and their flow rating at set pressures.

Fpt eliminates the need for users to perform complicated tasks such as calculating flow rates calculating performance corrected flow and graphing flow curves.

Hydrants open during the flow test are recorded and totalled to give the rating fire flow.

We have only shown the most popular tips sizes.

Quickly determine you water supply capabilities with our on line application for graphing fire hydrant flow test information on a logritmic graph n 1 85.

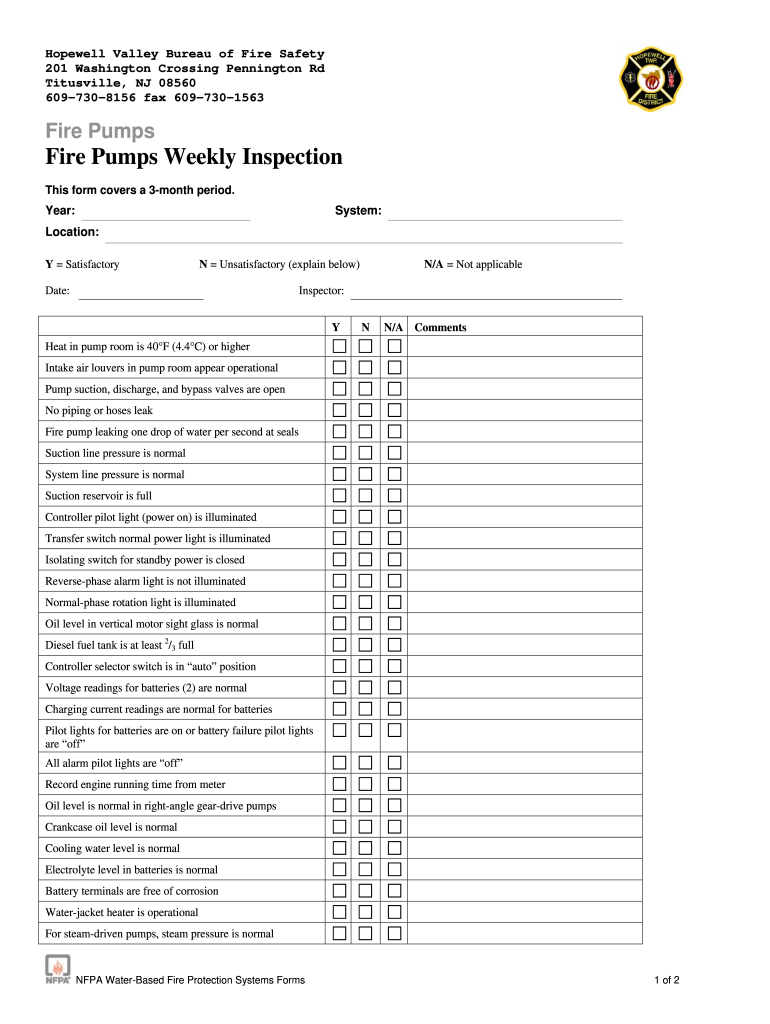

To help ensure the fire or booster pump is working there needs to be periodic inspection maintenance and testing of the pump.

Pressure readings are taken as the pump is run through its.

Fire pump tester software fpt allows fire protection contractors fire protection engineers and building managers to collect fire pump test data in a professional and comprehensive format.

Interna onal fire service training associa on ifsta fire protec on publica ons fire stream prac ces 7th edi on.

It meets the nfpa 1901 class a pump rating test and iso requirements for annual pump or service test.

The annual fire pump flow test is a full test of a pump s capabilities and is arguably the most critical test.

Solid bore nozzle flow chart.

It can also uncover any problems with the pump s water supply such as closed valves or obstructions.

Download a pdf of our user s guide and sample report for more information about the software.

The hoses are run to a safe location where the flow of water will cause no damage.

4 5 care should be taken to avoid causing nuisance during and after the tests.

Fire flows can cause damage to surroundings e g vehicles pedestrians landscapes and can cause flooding in the vicinity or remote to the site.

All nozzle pressures are pitot gauge readings not pump pressure gauge readings.

A separate checklist for electric pump and diesel pump is attached at the end of the document.